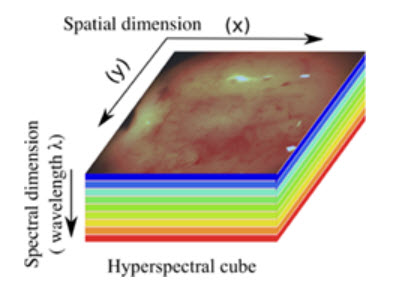

Hyperspectral imaging is part of a class of techniques commonly referred to as spectral imaging or spectral analysis.

Normally Hyperspectral Imaging and Multi spectral Imaging are used in similar context but these are two different types of Imaging.

A multispectral image is one that captures image data within specific wavelength ranges across the electromagnetic spectrum. The wavelengths may be separated by filters or by the use of instruments that are sensitive to particular wavelengths, including light from frequencies beyond the visible light range, i.e. infrared and ultra-violet. Multispectral imaging measures light in a small number (typically 3 to 15) of spectral bands.

The difference between hyper- and multi-spectral is sometimes based incorrectly on an arbitrary “number of bands” or on the type of measurement. Hyperspectral imaging uses continuous and contiguous ranges of wavelengths (e.g. 400 – 1100 nm in steps of 0.1 nm or very near to this nm) whilst multispectral imaging uses a subset of targeted wavelengths at chosen locations (e.g. 400 – 1100 nm in steps of 20 nm or more)

One of the main application areas of Hyperspectral Imaging in Machine Vision or inspection systems is Food Processing.

In the food processing industry, hyperspectral imaging, combined with intelligent software, enables digital sorters (also called optical sorters) to identify and remove defects and foreign material (FM) that are invisible to traditional camera and laser sorters. By improving the accuracy of defect and FM removal, the food processor’s objective is to enhance product quality and increase yields.

Adopting hyperspectral imaging on digital sorters achieves non-destructive, 100 percent inspection in-line at full production volumes. The sorter’s software compares the hyperspectral images collected to user-defined accept/reject thresholds, and the ejection system automatically removes defects and foreign material.

The recent commercial adoption of hyperspectral sensor-based food sorters is most advanced in the nut industry where installed systems maximize the removal of stones, shells and other foreign material (FM) and extraneous vegetable matter (EVM) from walnuts, pecans, almonds, pistachios, peanuts and other nuts. Here, improved product quality, low false reject rates and the ability to handle high incoming defect loads often justify the cost of the technology.

Commercial adoption of hyperspectral sorters is also advancing at a fast pace in the potato and other vegetable processing industry where the technology promises to solve a number of outstanding product quality problems.

Multispectral Imaging is used in Mine Detection, Missile Detection, Space applications etc.

Spectral Bands and their usage:

- Blue, 450–515..520 nm, is used for atmosphere and deep water imaging, and can reach depths up to 150 feet (50 m) in clear water.

- Green, 515..520–590..600 nm, is used for imaging vegetation and deep water structures, up to 90 feet (30 m) in clear water.

- Red, 600..630–680..690 nm, is used for imaging man-made objects, in water up to 30 feet (9 m) deep, soil, and vegetation.

- Near infrared(NIR), 750–900 nm, is used primarily for imaging vegetation.

- Mid-infrared(MIR), 1550–1750 nm, is used for imaging vegetation, soil moisture content, and some forest fires.

- Far-infrared(FIR), 2080–2350 nm, is used for imaging soil, moisture, geological features, silicates, clays, and fires.

- Thermal infrared, 10400-12500 nm, uses emitted instead of reflected radiation to image geological structures, thermal differences in water currents, fires, and for night studies.

We – Online Solutions represent Teledyne DALSA who make Multispectral Imaging Line Scan Cameras at high speeds.

The new Piranha4 quadlinear RGB + NIR / Mono cameras provide industry leading speeds to meet future requirements of higher throughput in multi-spectral imaging applications.

Based on Teledyne DALSA’s unique CMOS line scan technology, the Piranha4 multi-spectral camera delivers superb color plus near-infrared (NIR) fidelity, spectrally independent outputs, all in a compact footprint and with an easy to use interface. New features include multiple regions of interest for data reduction and regional calibration, sub-pixel spatial correction, white balance and color calibration tools.

Online Solutions can provide solutions based on Hyperspectral and Multispectral Imaging for different needs.

Note: The above article is a collection from various web sites, manufacturers and distributors / integrators of Hyperspectral Imaging & Multispectral Imaging. If any company/individual finds any ownership of contents – they can let us know at [email protected] to either change or remove the contents. Article is provided only for the information purposes and facts can be cross verified by the readers.