Popularization of electric vehicles (EVs) is an effective solution to promote carbon neutrality, thus combating the climate crisis. Advances in EV batteries and battery management interrelate with government policies and user experiences closely.

The types of EVs that use batteries include:

Besides the machine and drive as well as the auxiliary electronics, the rechargeable battery pack is another most critical component for electric propulsions and await to seek technological breakthroughs continuously

Most electric vehicles are powered by lithium-ion batteries and regenerative braking, which slows a vehicle down and generates electricity at the same time.

Currently, among all batteries, lithium-ion batteries (LIBs) do not only dominate the battery market of portable electronics but also have a widespread application in the booming market of automotive and stationary energy storage. The reason is that battery technologies before lithium (e.g., lead–acid or nickel based batteries) and battery technologies beyond lithium, so called ‘post-lithium’ technologies, such as sodium-ion batteries (SIBs), mainly suffer from significantly lower energy density and specific energy compared to state-of-the-art LIBs.

There are several types of lithium-ion batteries, with lithium nickel manganese cobalt oxide (NMC) and lithium iron phosphate (LFP) batteries being the most common ones used in EVs.

Lithium-ion batteries are used in EVs because they:

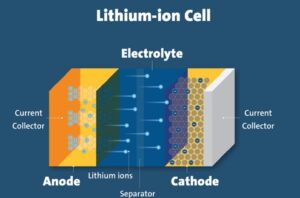

Lithium-ion batteries, like all batteries, store energy and convert it to electrical energy when in use. This electricity is produced by the movement of electrons, which are small particles with a negative charge that are found in all atoms. Chemical reactions within the battery move these electrons from one electrode to another. There are two electrodes in a battery: the anode (a negative electrode) and the cathode (a positive electrode). Electrons start off in the anode and then move to the cathode through an electrolyte medium, which can be either liquid or solid. When the battery is in use, the electrons move from the anode electrode to the cathode electrode; when the battery is charging, they move from the cathode to the anode. Another key component of a battery is the separator, a thin, porous membrane that, as the name implies, separates the anode and cathode electrodes while enabling the lithium ions to move from one to the other. It also prevents short circuiting, which happens when an electric current flows down a wrong or unintended path.

Production Process of Battery:

The production of the lithium-ion battery cell consists of three main process

steps: electrode manufacturing, cell assembly and cell finishing.

Electrode Manufacturing:

a) Mixing – Quality Features:

b) Coating – Quality Features:

c) Drying – Quality Features:

d) Calendering – Quality Features:

e) Slitting – Quality Features:

f) Vacuum Drying – Quality Features:

CELL ASSEMBLY:

a) Separation – Quality Features:

b) Stacking – Quality Features:

c) Packaging – Quality Features:

d) Electrolyte Filling – Quality Features:

e) Winding – Quality Features:

f) Packaging – Quality Features:

g) Electrolyte Filling – Quality Features:

CELL FINISHING:

a) Roll Pressing – Quality Features:

b) Formation – Quality Features:

c) Degassing – Quality Features:

d) Aging – Quality Features:

e) EOL Testing – Quality Features:

With the above information on the steps involved in manufacturing batteries, let us some areas of quality inspection or defect inspection or measurement kind of Machine Vision Inspections that can be applied related to those quality features listed in each step of the production process.

TELEDYNE DALSA and INSPECTION:

Quality Assurance for Lithium-ion Battery Production While lithium-ion battery production may be conceptually simple with coated electrode stacked sheets and an electrolyte solvent, the actual process is fairly complicated and sensitive. The thickness of the coatings on the electrodes can have a significant effect on a battery’s performance or even its stability. Line scan cameras powered with machine learning algorithms can help automate and streamline the quality assurance stage of lithium-ion battery manufacturing. A line scan camera is a camera that can be mounted on a factory production line to monitor the production of materials as they are moved through the manufacturing process. Line scan cameras are well-suited to inspection of electrode sheets, since the sheets are run at high speeds from big spools through the coating and stacking process. Laser profiling from inspection cameras can cover the whole manufacturing process of lithium-ion batteries. The cameras can measure the thickness of the electrode sheets and coating, look for surface defects on the sheets such as dents, scratches or bent edges, measure the dimensions of the battery casing for cylindrical or pouch batteries, and monitor the quality of the weld of the external terminal on the batteries.

The main challenges in many of the electrode inspection tasks is the speed of the

process and the need to identify ever smaller defects. The camera must be able to keep up with the production speed of the machines and therefore have a high line rate while providing enough sensitivity to allow the use of short exposure times and have enough pixels to cover as wide a field of view (FOV) as possible. Linea 8K and 16K line scan cameras with Camera Link interface are a popular choice in that industry. For slower lines and processes our Linea GigE cameras dominate, but also Linea 4K and Genie Nano 2MP area scan cameras are used for various inspection tasks during the production of lithium-ion batteries.

In addition to the various inspection tasks associated with the electrode manufacturing process, such as post-coating, post-calendaring and post-slitting and -separation inspection, other machine vision solutions can contribute to economic processes, e. g. laminating, winding, housing insertion and welding, sealing, grading and finally packaging processes. With a broad portfolio of machine vision components including the necessary frame grabbers, interfaces and software solutions, Teledyne Dalsa is well equipped to enable powerful inspection solutions for lithium-ion battery production.

Teledyne DALSA has introduced AxCIS – a fully integrated line scan imaging module which combines sensors, lenses, and lights all-in-one. This Contact Image Sensor (CIS) is easy-to-use and offers a lower system cost for many demanding machine vision applications as well as superior signal-to-noise ratio and a Camera Link HS SFP+ fiberoptic interface. AxCIS can fit anywhere in your system, even with limited vertical clearance and it’s easy to install, with no complex alignment or calibration required and a single 24v power supply.

We Online Solutions (Imaging) Pvt. Ltd., Chennai India can provide suitable solutions through components like Cameras and Frame grabbers from Teledyne DALSA, Lenses from Schneider-Kreuznach and Filters from Midopt towards the EV battery Inspection.

Note: Above Blog is written with contents taken from different web sites of manufacturers, Magazines, Research papers that are open to public. Any content found objectionable, wrong info or not to be used by us – can be informed to us at [email protected] and we can correct or remove the content based on the genuineness of the mail received.

We'll be glad to help you! Please contact our Sales Team for more information.

We'll be glad to help you! Please contact our Sales Team for more information.