In any project that relates to converting a real world object to Image whether it is entertainment or scientific or industry automation, light plays the key role in success of the need in respective domains mentioned. Unfortunately, in many cases, lighting is given the least priority or always done with an intention to manage the images through software filters etc. Lighting is not given the due respect in terms of budgeting to develop a system.

When we talk about lighting or display, the two key words that come in to note are contrast and brightness. Brightness refers to the overall lightness or darkness of the image. Contrast is the difference in brightness between objects or regions. Brightness is a relative term. It depends on the viewer’s or users perception. Contrast can be simply explained as the difference between maximum and minimum pixel intensity in an image. Lighting does this effect to remove unwanted elements on an image and makes the pre processing lighter to get an Image directly ready for the analysis.

The following Machine Vision lighting sources are now commonly used in Machine Vision: Fluorescent, Quartz Halogen – Fiber Optics, LED – Light Emitting Diode, Metal Halide, Xenon , LASER patterns.

Machine Vision Light sources can be of multi colors or single color. Most of the applications demand only a monochrome that is a single color light depending on the object and its surface reflectiveness and the parameters or features to be extracted from the image to arrive at a conclusion in terms of output.

The other important criteria to be noted in Machine Vision lighting are Geometry – spatial relationship among the object viewed, light and camera, that includes angles, near, far etc., Pattern – the shape of the light projected onto the object, Wavelength, or Color – depending on the reflection and absorption of light by the object (recollect our school physics on Light that talks about light reflection and also how our eye visualizes the color of an object etc..), Filtering applied on lights to cut unwanted wavelengths or direction of light falling or enhance particular wavelength etc..

Machine Vision Lighting should also be considered based on the space constraints in the project and the ambient lighting that disturbs the images as sometimes it is not possible to have a controlled environment to apply lighting.

Though there appears to be too many times of lighting, the techniques involved will only fall under the categories like Back Lighting, Diffuse Lighting , Bright Field and Dark Field

Bright field versus dark field geometry is one of the important and difficult decisions to be done in all Machine Vision projects. Bright field lighting is the more commonly used, which involves keeping lights between 90 and 45 degrees from the object. Dark field lighting involves keeping lights between 0 and 45 degrees. Dark Field is effective when object is with highly reflective surfaces.

In Bright Field Lighting, the light source will be scattered less by the object’s surface and more light will be reflected back into the camera there by producing bright images. But in Dark Field lighting the scattered light is captured by the camera which gives more details on edges, scratches etc.

In all lighting, the camera should also have the facility to adjustments to maintain the uniformity. Terms like PRNU, FLAT FIELD Correction, Color Correction, Lens barrel distortion correction would come in to picture for better imaging.

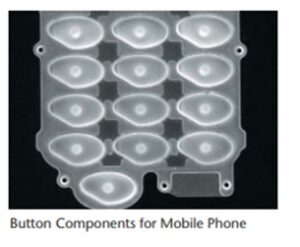

Bright Field 360 Degree LED Illumination:

Dark Field Illumination on the same Mobile buttons ( that is light with Low Angle)

Back Light: ( to provide the contour or edge contrast)

Coaxial or indirect lighting samples

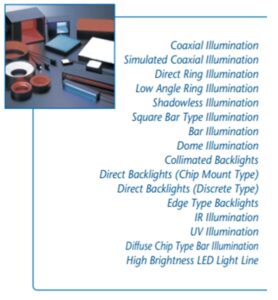

Lighting Types manufactured broadly.

As known Line Scan Cameras need to have illumination specific to Line on the object that is viewed by Line Scan camera. Depending on the object, project the line lights are available in RED, WHITE, Multispectral colors etc..

There are many companies that concentrate only on Lighting there by working on these concepts of lighting and keep innovating to come out with lights very specific to projects around. The Lighting systems may be expensive but would provide very the convenience of very less project time to complete the project successfully.

We Online Solutions in India represent few companies for their Lights and can work with the clients for lighting solutions based on the project need. This write up here also emphasizes the need to work out proper budgeting for Light systems for a project as in our experience we have seen many projects floored due to improper funding for light systems.

The above write up has collections from different light manufacturers also. All images are courtesy – Moritex. Any objection to any material published here can be notified to us at [email protected] and the contents can be reworded or removed as needed. This write up is an attempt to give some insight on importance of Lighting in Machine Vision projects.

Blog Article by S Sukumar, Director – Projects, Online Solutions (Imaging) Pvt. Ltd., Chennai INDIA.

We'll be glad to help you! Please contact our Sales Team for more information.

We'll be glad to help you! Please contact our Sales Team for more information.