Machine Vision is primarily used in all manufacturing places for quality and guidance purposes. Machine Vision involves understanding of the project in terms of conventional algorithms to define pattern and match, measure, segment and categorize, color based differentiation etc.. Machine Vision algorithms at some specific tasks of identification, classification and anomaly detection does not give effective results as expected. This is because of more of mathematical and logical algorithmic work and not based on LEARNING.

Deep Learning may be a sub set of artificial intelligence helps in this situation of Learning. In most cases the users could specifically show and determine all the above referred tasks which means a human brain in course of time has learnt with some modeling and training. Deep Learning does something similar.

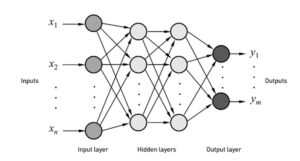

Deep learning technology makes use of deep neural networks to perform its classification function. These neural networks take inspiration from the way the human brain processes sensory input

in order to interpret data. Specifically, deep learning technology leverages the convolutional neural network (CNN)—or close relatives thereof—to analyze images. The CNN may also be referred to as the model.

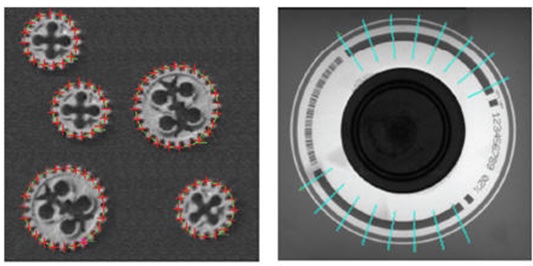

CNN or in simple model has to be trained first with as many as samples possible reference images or image sets to accomplish the task taken. These reference image set should have the images with all possible variations within and this has to be carefully chosen and can be large. The objects to be used for Image sets should be captured using the same camera, lens and lighting arrangement and stored.

Many of the Deep Learning tools come with a GUI to take these Image sets and do some minimal processing to label or manually label the images for classification. Labelling of the data set is so intrinsic to the effective training of the model. Training the model from scratch may involve adjusting numerous parameters.

Once trained and tested, the deep learning model can be implemented in run time to perform the task. On the performing process, if there occurs failures then those set of images to be added for a training again and implemented.

Deep learning can excel in Identification, Defect detection, OCR etc., but not suitable or does not excel in measurement based Metrology, high Precision pattern matching and Code reading etc.

Hence deep learning is not an alternative to Machine Vision but can be treated as an assisting tool or subset to accomplish Machine Vision tasks.

Any Machine Vision developer should now have the knowledge of dividing the project in hand into tasks to be done using conventional Machine Vision algorithms and Deep Learning algorithms. Both of these can be implemented in a single project through proper software development and implementation tools.

Online Solutions (Imaging) Pvt. Ltd., Chennai, India. represents Teledyne DALSA in India for their various products like Cameras, Frame grabbers, Software etc. The software SAPERA PROCESSING is available with conventional and some proprietary tools and also the deep learning tool called Astrocyte.

Kindly visit our web site www.onlsol.com to learn more on this.

Note: This blog may contain collection of information from various sources and web sites. If any of the contents found to be under any copyright or any protection of data type then kindly inform us at [email protected] to alter or remove the contents. None of the usage if any is not intentional or with commercial aspect.

We'll be glad to help you! Please contact our Sales Team for more information.

We'll be glad to help you! Please contact our Sales Team for more information.